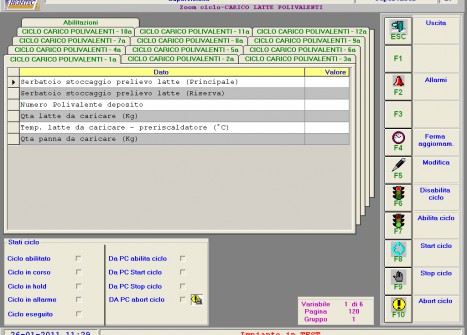

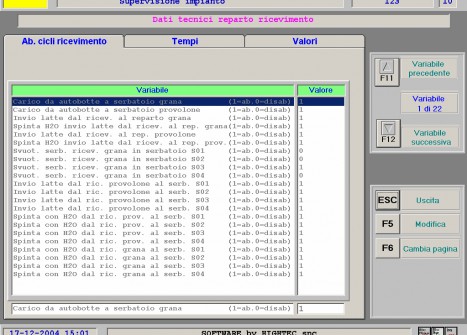

The milk production supply chain tracking process starts from when the product coming from the farm is unloaded, going through the various

processes until it becomes a finished product (dairy products and cheeses).

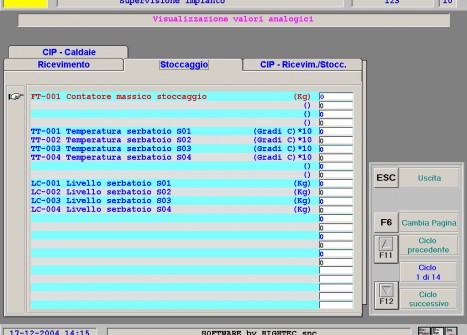

The milk conditions (temperature – PH) are recorded automatically for every single unloading stage and, by creating a product sheet,

the chemical analyses carried out subsequently by a laboratory through the samples

collected are added.

Therefore at any time it is possible to always trace back to the characteristics of the milk that was used for the production of a certain batch, in order to identify any processing abnormalities of the production chain.

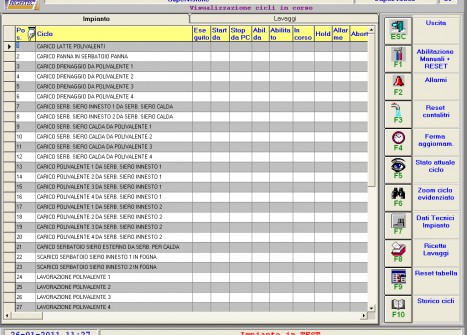

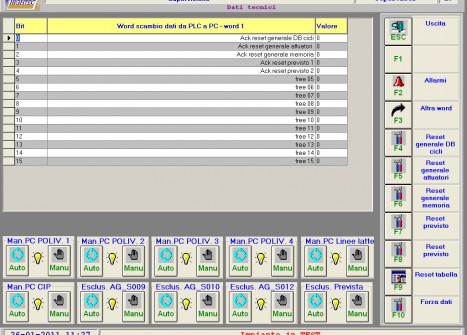

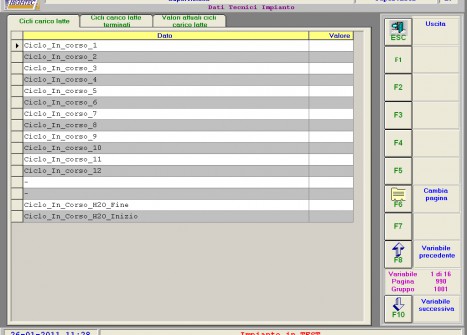

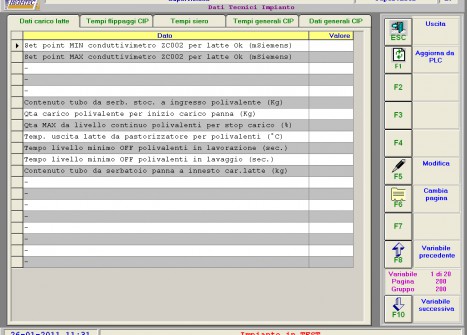

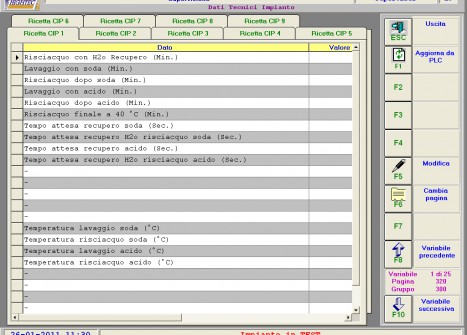

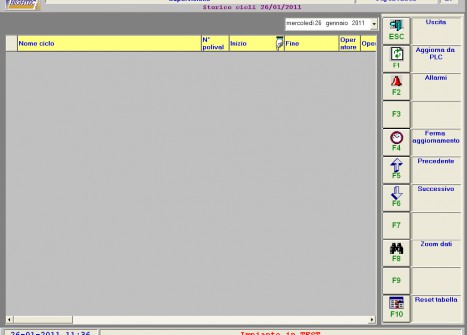

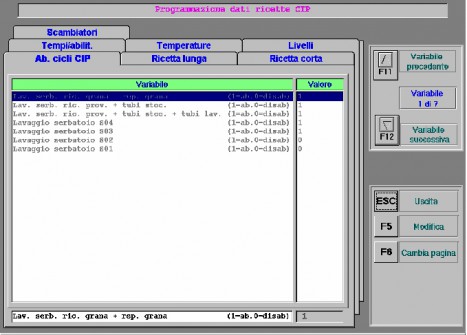

An important aspect of the milk supply chain is tracking

the sanitisation of the systems.

All the washing and sanitising cycles are tracked, recording the start time and duration and indicating the washing temperatures and concentrations of sanitising solution

with which the systems were washed.