Ham sorting line with conveyor belts and digital scales, for sorting

the product according to the preset weight range, with daily and/or monthly quantity and weight statistics, with thepossibility to sort by supplier.

All posts by info@laravella.com

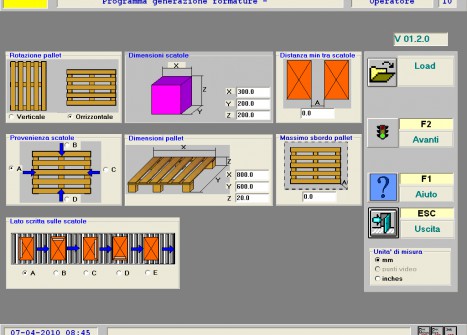

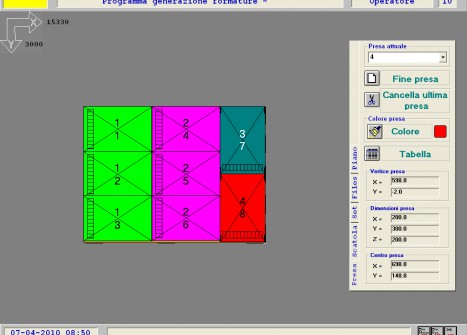

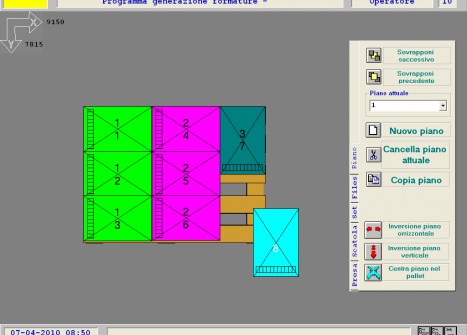

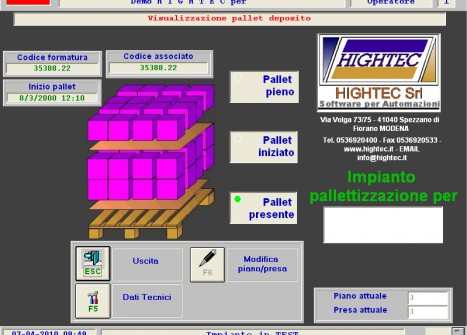

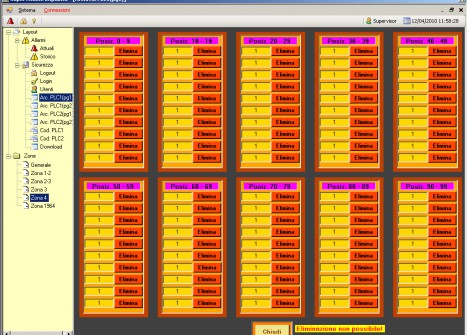

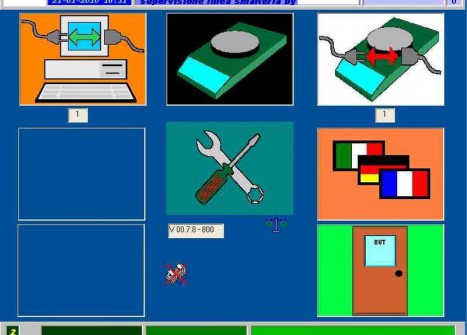

Generation of palletisation format parameters

Software for the automatic and/or semi-automatic generation of parameters for the palletisation robot, with the possibility to select

the pallet size, box size, distance between boxes, box rotation and number of layers per pallet,

differentiation of layers with straps, with the possibility to save the various formats and transfer them to various palletisation robots

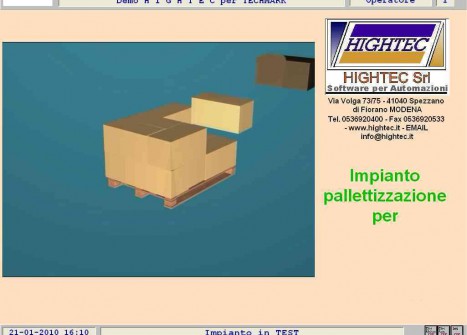

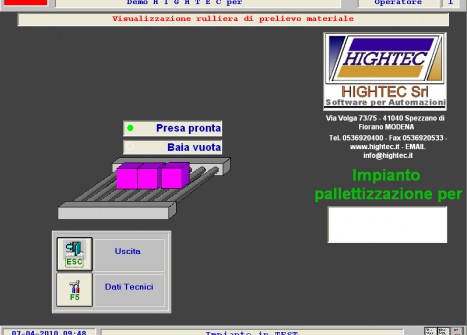

Complete palletisation system

Complete palletisation system

Software for the complete management of the last stage of the production line: from box sorting management, to palletisation and pallet handling.

The system manages the reception of production orders and their processing, box sorting through bar codes or RFID,

box palletisation, pallet card printing, packing list printing for outgoing pallets (with relative transmission of the confirmation to the management system).

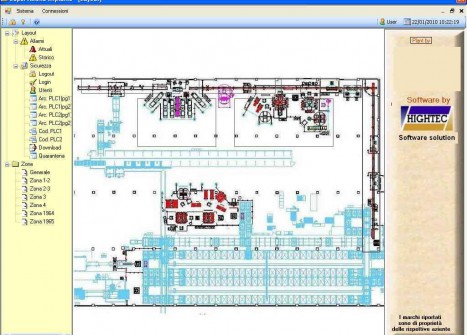

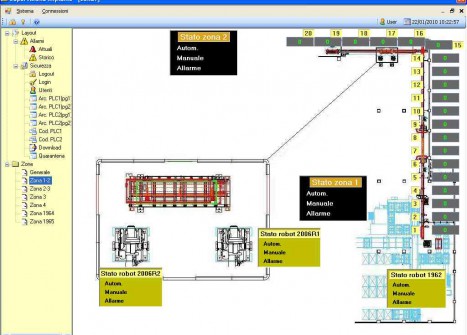

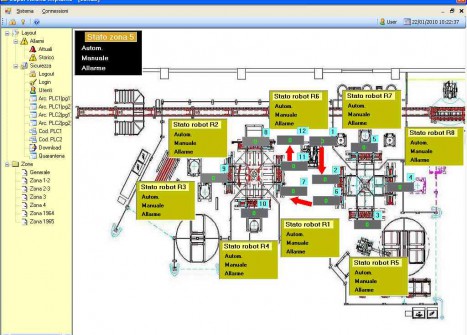

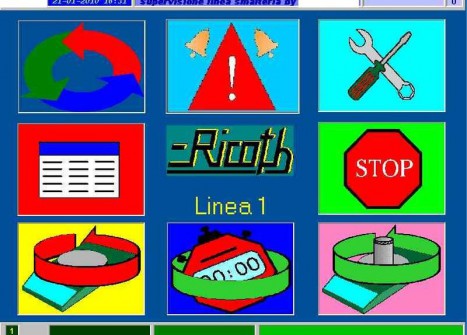

General product handling tracking

on-line product tracking supervision and management system, encoding with bar codes or data matrix,

interfacing with anthropomorphic robots for processing of on-line products, generating reports for the jobs performed

and for the jobs to be performed, production statistics and real time display of the status of the

various processes and the relative results.

All the information is available locally or exported to the company management system.

Mixing system

Dosing and mixing systems:

mixing and dosing plant management and supervision systems; management of single recipes and/or consecutive batches; management of extraction from silos through augers, scales or weighing belts, with automatic correction of the parameters set; recipe creation, storage and recall in both manual and automatic mode;

bidirectional connection with the facility management system.

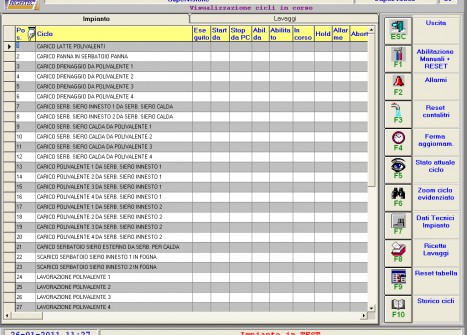

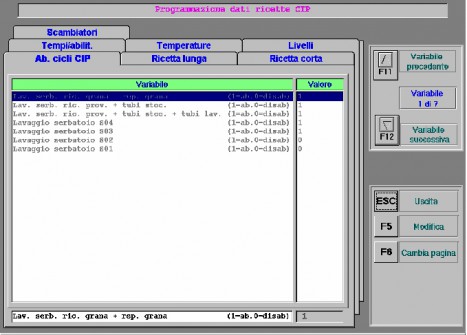

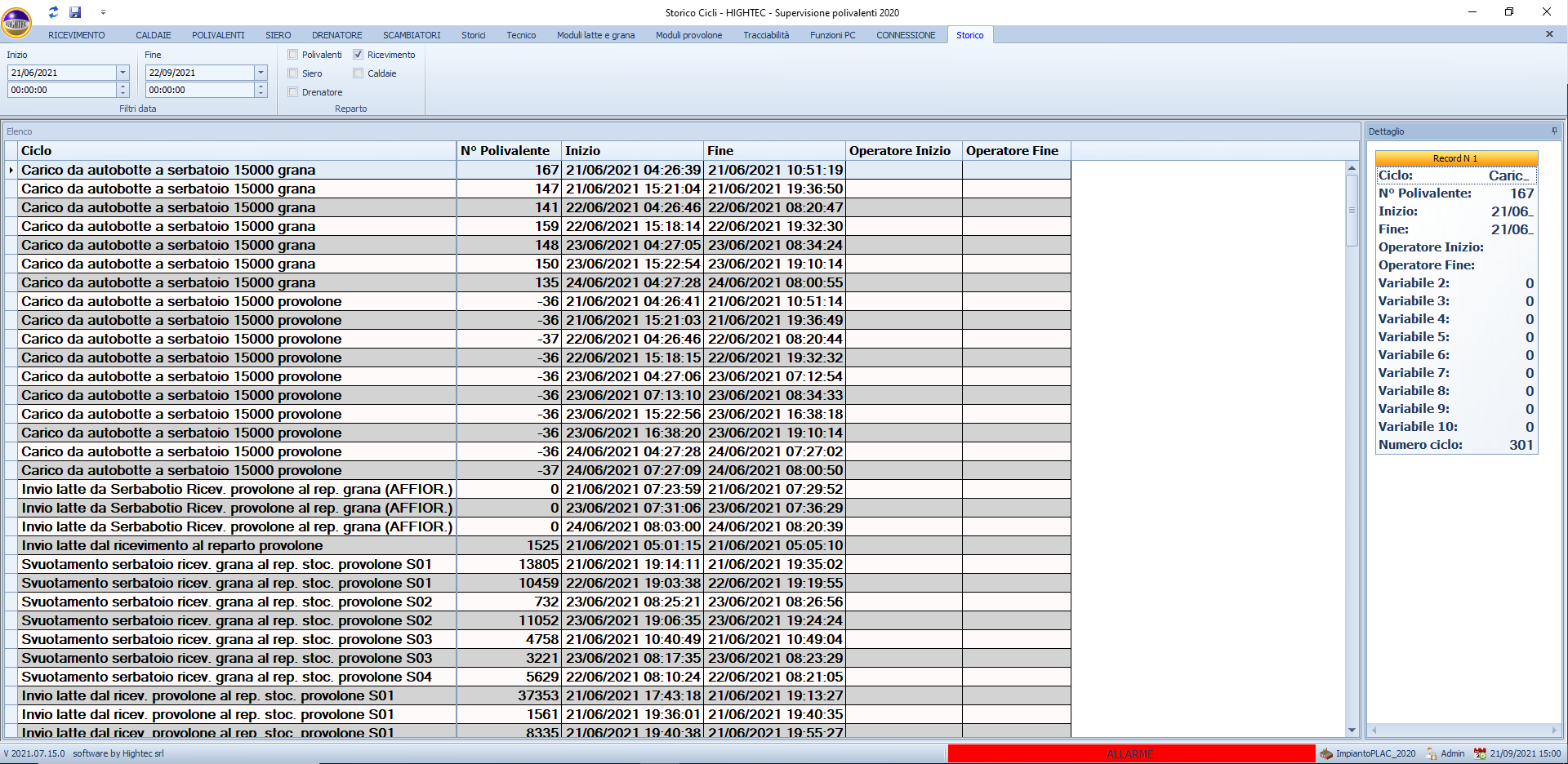

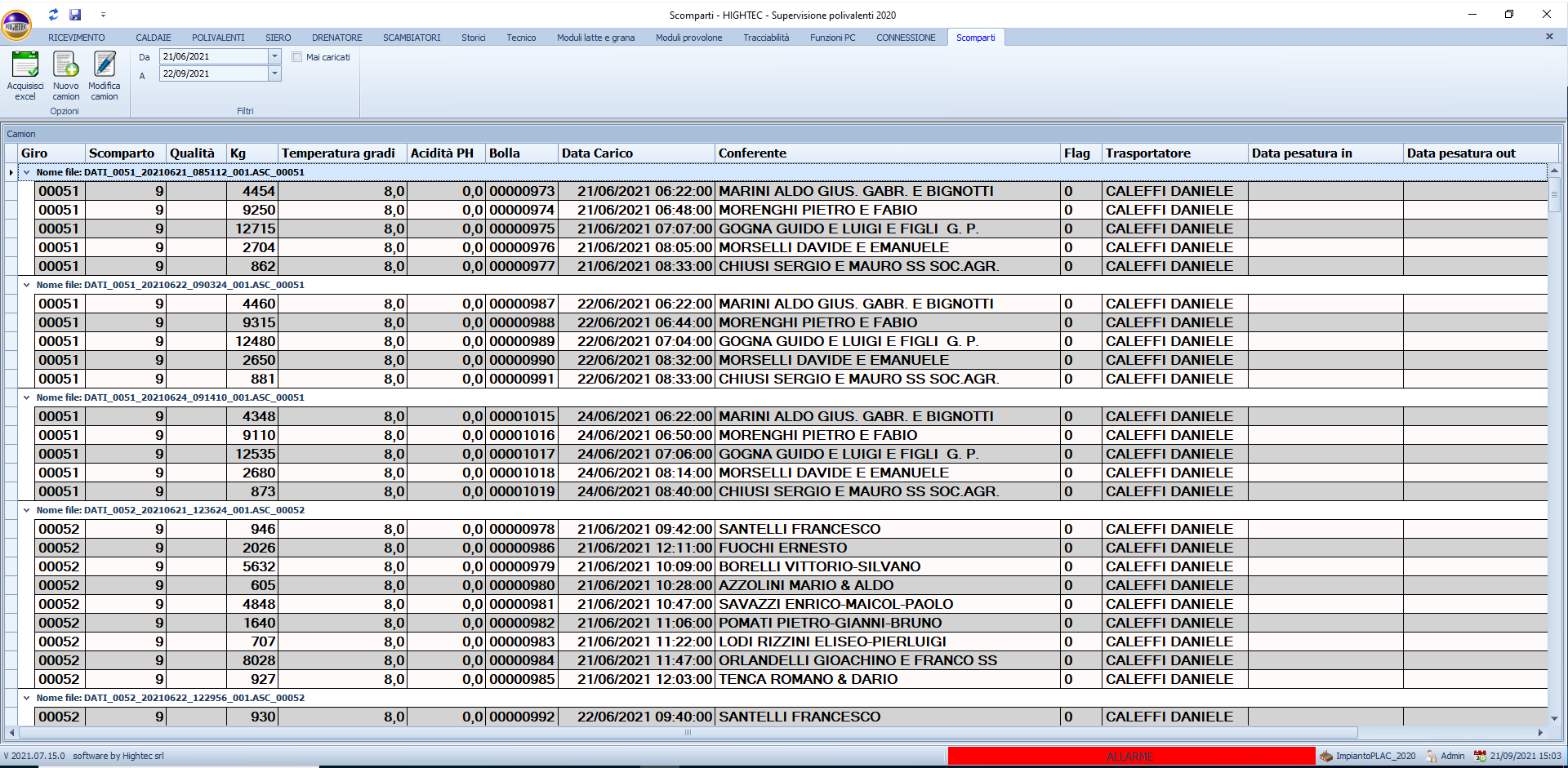

Milk production supply chain tracking

The milk production supply chain tracking process starts from when the product coming from the farm is unloaded, going through the various

processes until it becomes a finished product (dairy products and cheeses).

The milk conditions (temperature – PH) are recorded automatically for every single unloading stage and, by creating a product sheet,

the chemical analyses carried out subsequently by a laboratory through the samples

collected are added.

Therefore at any time it is possible to always trace back to the characteristics of the milk that was used for the production of a certain batch, in order to identify any processing abnormalities of the production chain.

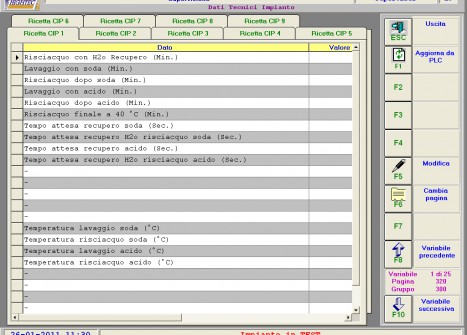

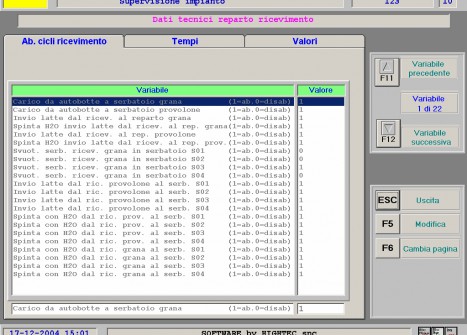

An important aspect of the milk supply chain is tracking

the sanitisation of the systems.

All the washing and sanitising cycles are tracked, recording the start time and duration and indicating the washing temperatures and concentrations of sanitising solution

with which the systems were washed.

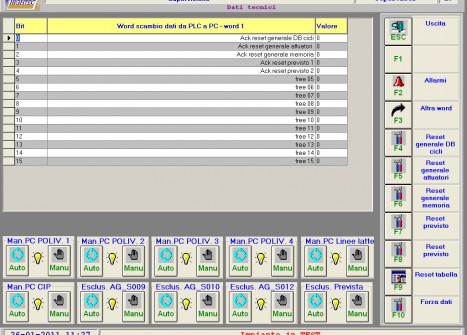

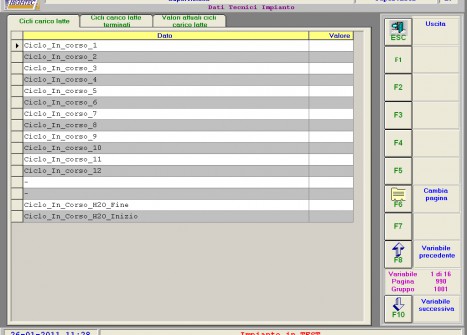

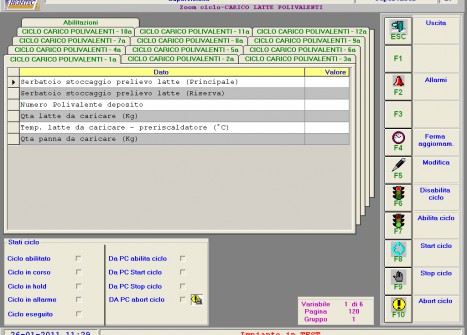

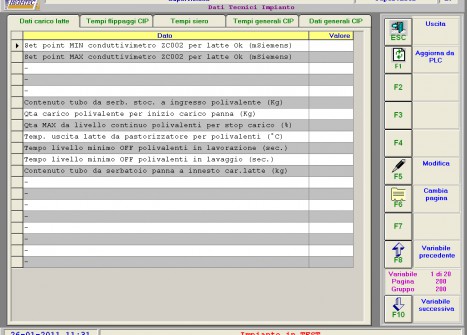

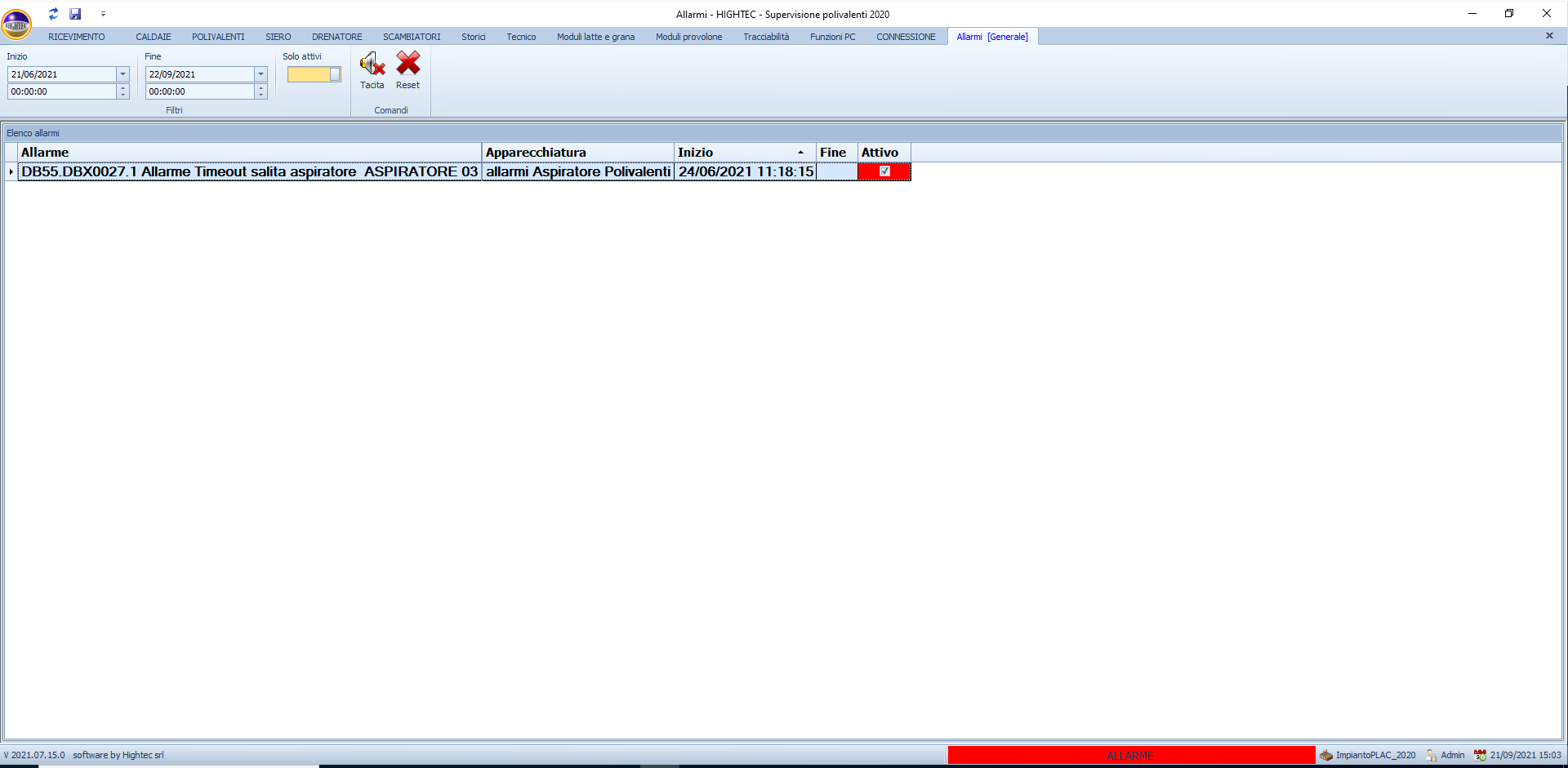

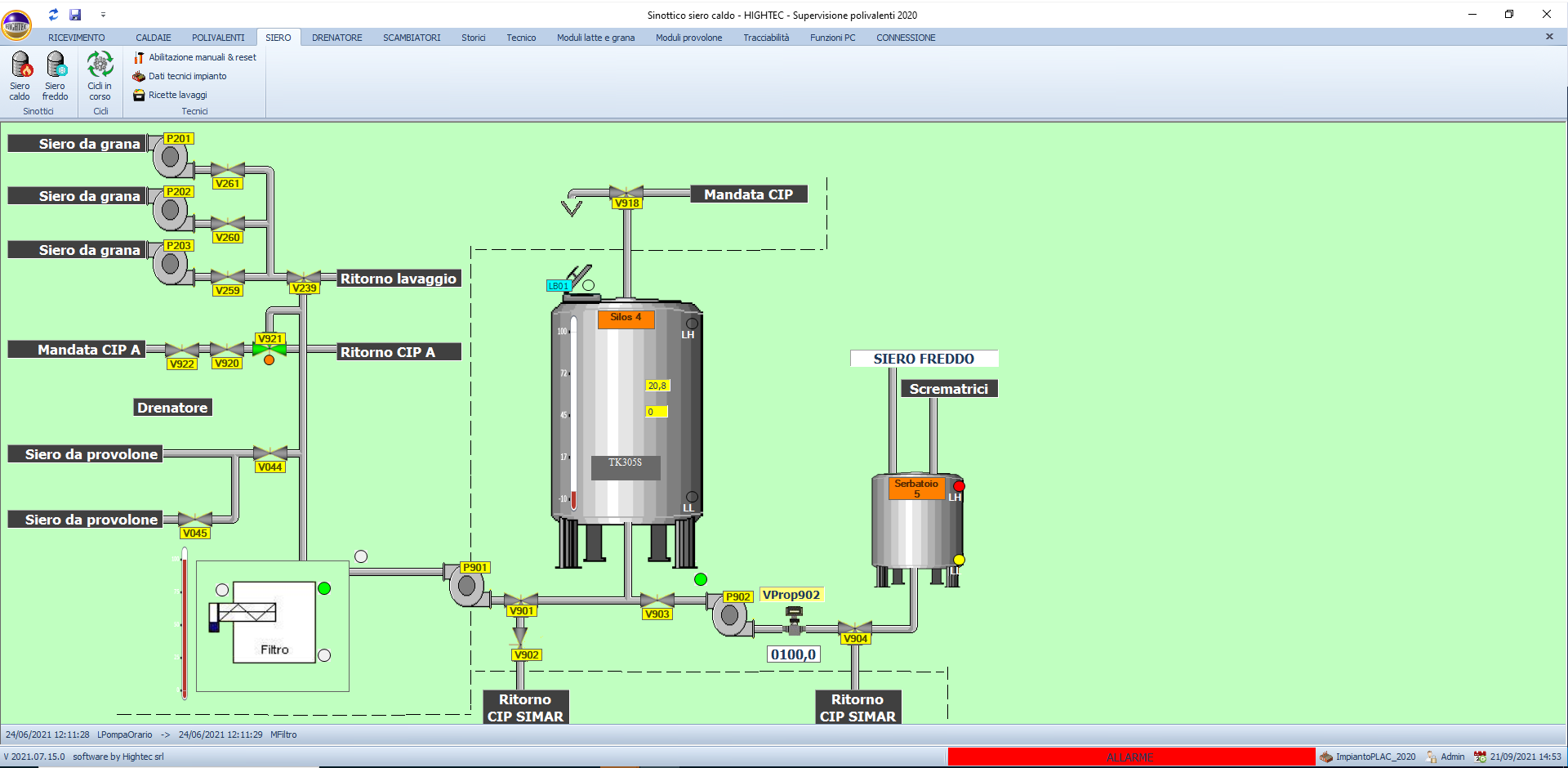

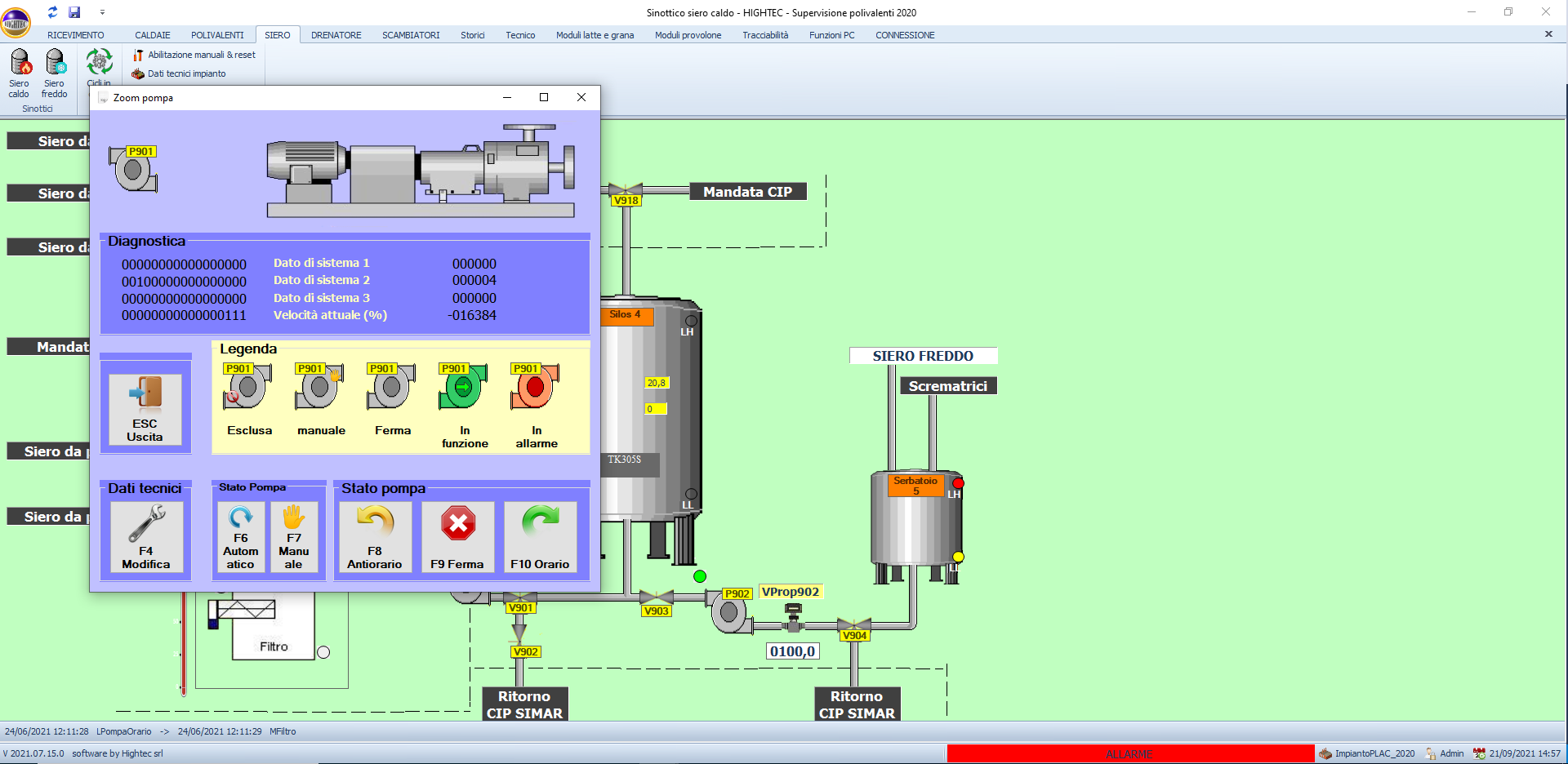

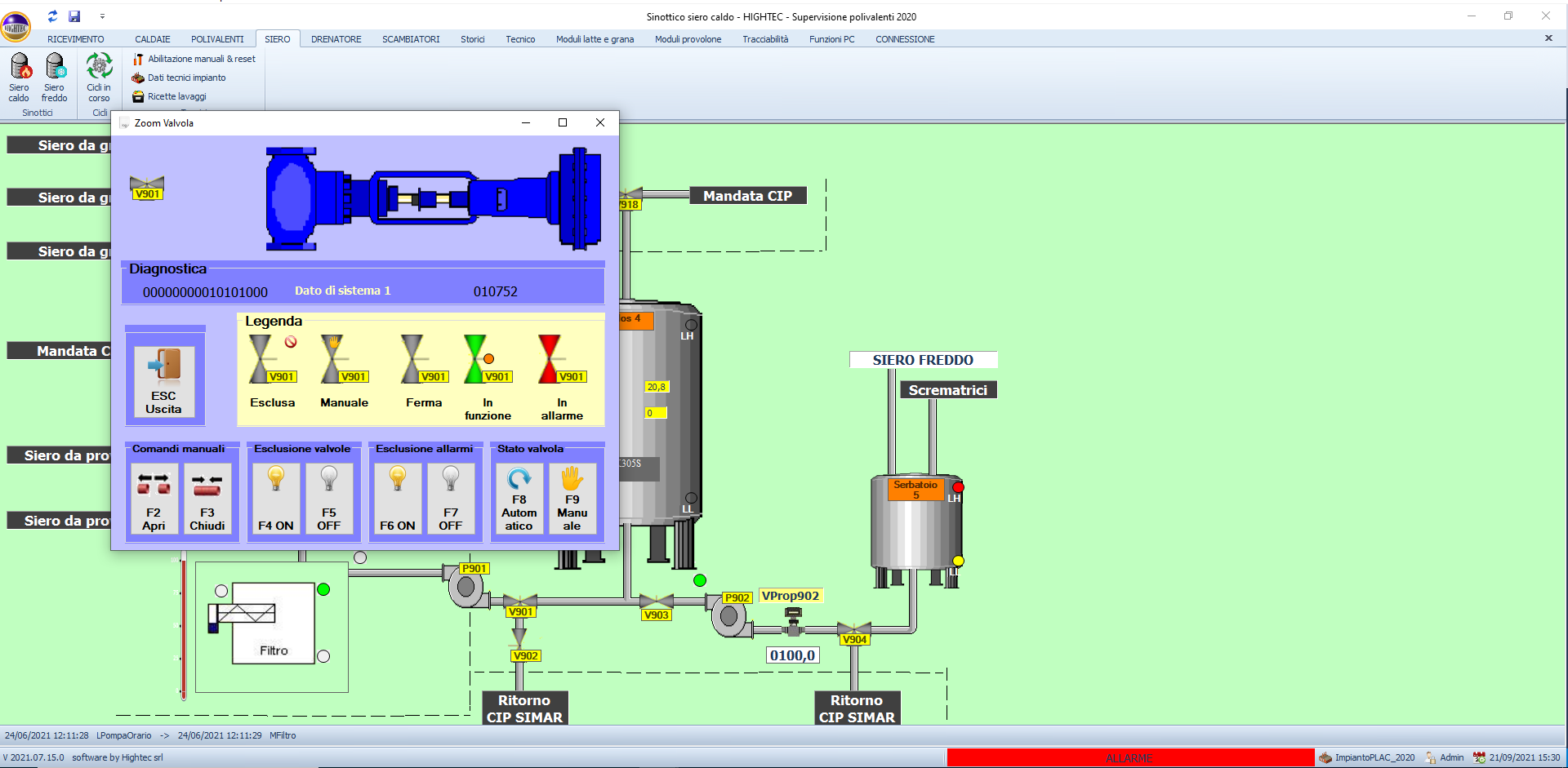

dairy industry

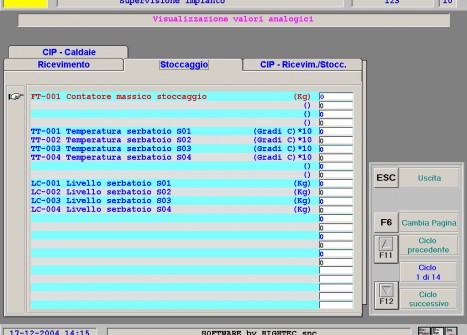

Dairy industry systems:

dairy industry facility management and supervision systems.

The system manages all the individual departments that may form a complete

production facility:

Milk reception and storage, milk processing in boilers for the production of Grana cheese

or in multipurpose tubs for the production of soft cheeses; pasteuriser management, whey processing complete automatic CIP for washing all the parts of the system.

Complete supervision with display on animated synoptic screen of all the

system components.

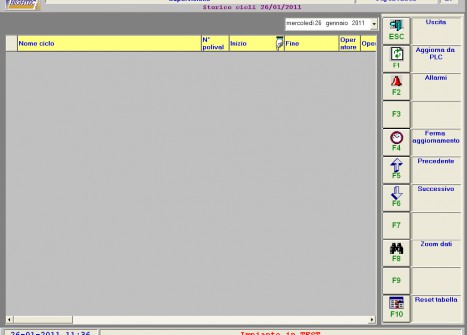

Database recording of all events occurred (start date/time and end of the cycle with quantities and/or temperatures)

Alarm activation with their duration,

Recipe programming,

Production parameter recording and production batch tracking.

(Italiano) Tracciatura filiera produttiva olio

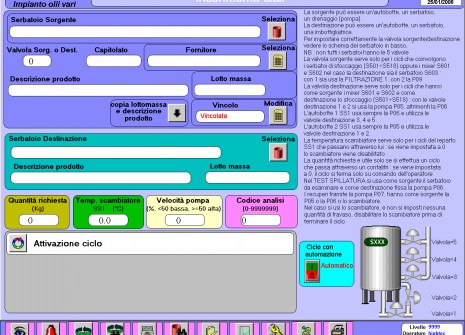

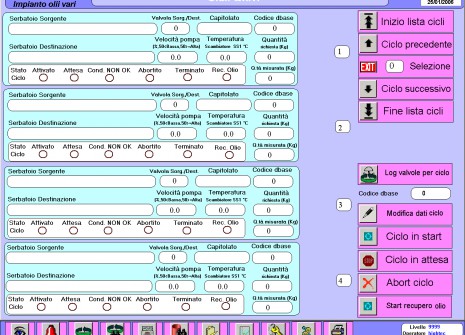

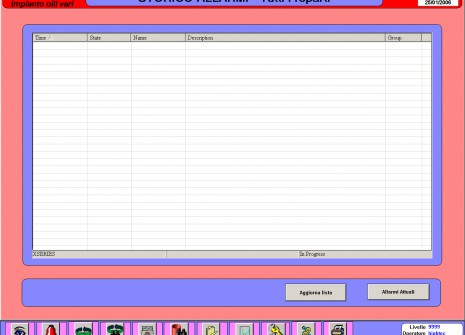

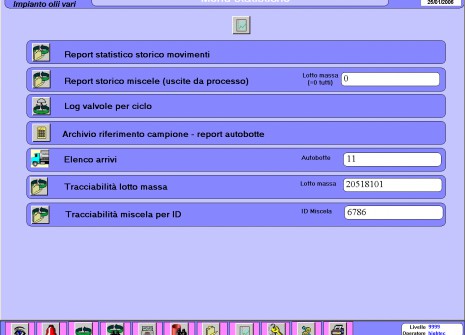

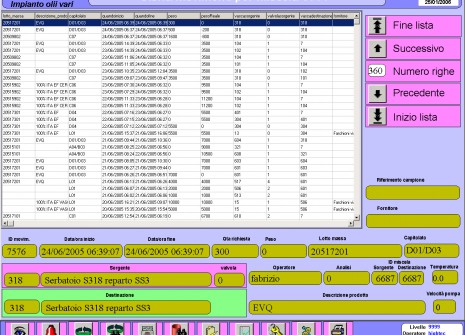

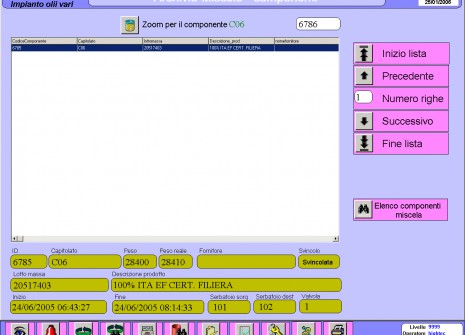

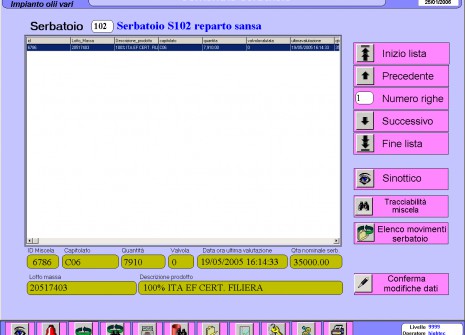

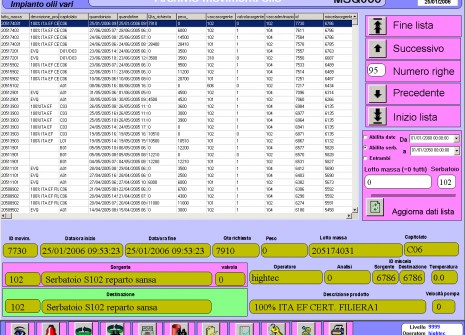

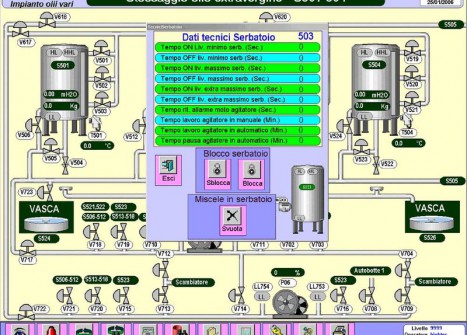

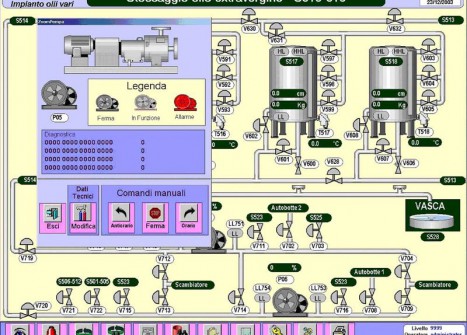

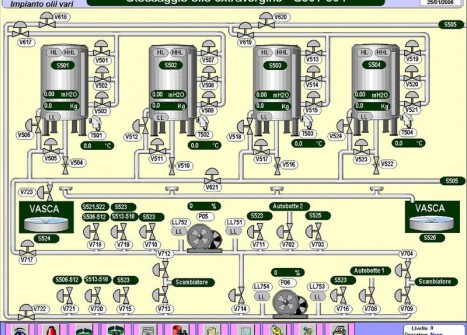

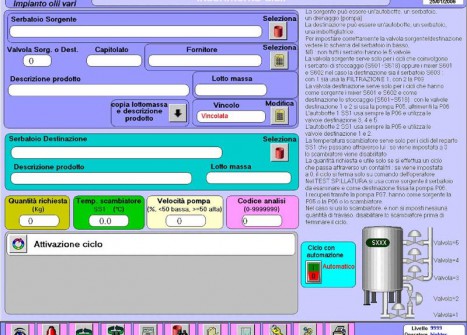

Oil handling plant

Oil mill management and supervision systems:

plant management and supervision systems for the production of edible oils.

The system manages all the departments for the reception, storage, mixing and transmission to the bottling machines.

The management system concerns both the PIPING (i.e. all the transfers from the various tanks) and mixing to achieve the various BLENDS.

Total product traceability is managed with the possibility of tracing back from the final product to the various suppliers who produced the base oil for the blend.

All the components (tanks, valves, pumps, etc.) present in the facility are monitored on an animated synoptic screen as well as the status of the various PIPING cycles and compositions of the various BLENDS.

Database recording of all events occurred (start date/time and end of the cycle with tank intake and discharge quantities)

Alarm management with start time recording and duration, free message programming.

Glazing weighing system

Tile enamel weight control system:

the complete glazing lines are installed with

the enamel weighing systems.

By reading the enamel sheet data on the management system, the enamel is weighed in a guided manner for each application that requires it.

Through the screen, the operator is given instructions to weigh the enamel, check the density and the viscosity: the results and ranges

required by the enamel sheet are stored.