Production tracking program in ceramics plant, starting from the grinding department and going via the following departments

- grinding;

- atomisation;

- atomised storage;

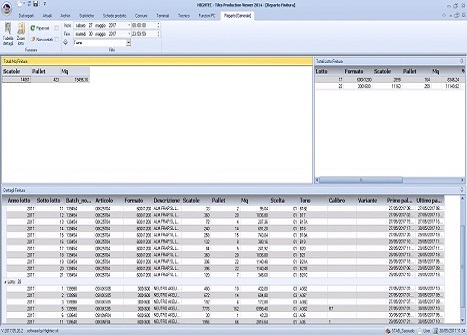

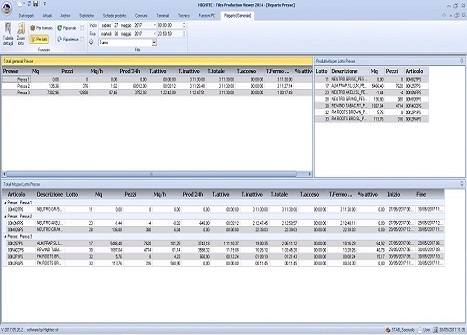

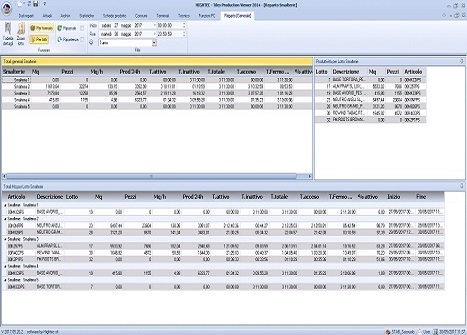

- presses;

- dryer;

- glazing;

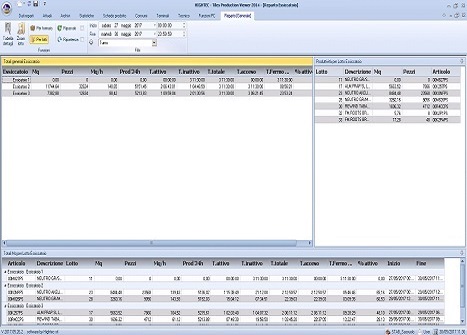

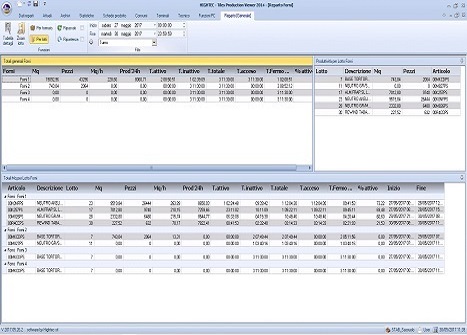

- kilns;

- squaring;

- sorting infeed;

- palletisation;

- finishing;

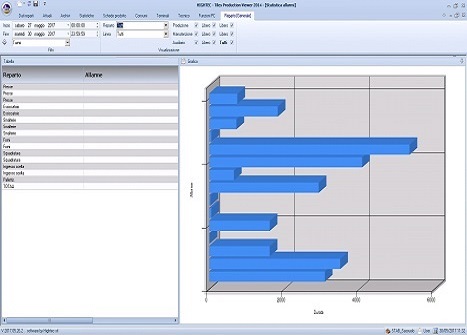

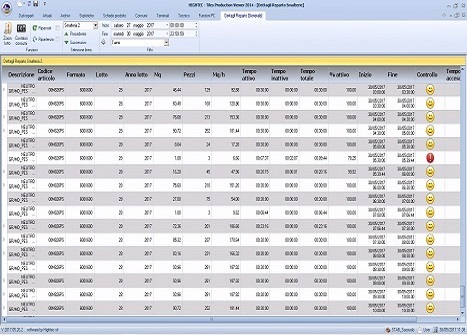

real time display of the yield and rejects, plant setting storage, production data totalisation, statistics customised by department,

interfacing with management system for data acquisition and production plans,

interfacing with management system to export production data,

interfacing with WWS for product pallet data transmission.

The management of the production supply chain includes the measurement of the consumption of gas, electricity and/or other significant parameters:

all aimed at recording the costs relating to the various production batches.